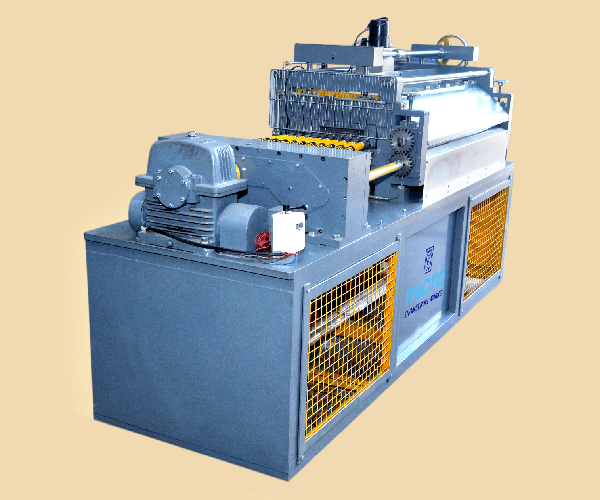

Sheet Sheering Machine ( Cutting Machine )

What Is Sheet Sheering Machine

Advantages

- Significantly lower price compared to a new machine, reducing initial capital investment. Allows businesses to allocate funds to other essential equipment or operations.

- No waiting period for manufacturing and delivery, as used machines are readily available. Immediate installation and integration into production lines.

| TECHNICAL SPECIFICATION | DETAILS |

|---|---|

| Process | Residual Stress Relieve |

| Material Thickness (mm) | 0.5-2 |

| Maximum Material Width (mm) | 760 |

| Flattening Gap Adjustment | Manual and motor drive |

| Machine Size (mm) | 762x1778x 1200 |

| Total Weight (kg) | 1000 |

Key Features of Cutting Machine for Stainless Steel:

The Cutting Machine delivers precise and clean cuts on stainless steel sheets or strips, ensuring high accuracy with minimal deviations. It supports various cutting methods, including shearing and laser, for different thicknesses and grades. Built with durable cutting tools, the machine handles the toughness of stainless steel, while its automated feed and alignment systems optimize efficiency. Surface protection mechanisms prevent scratches and damage during the cutting process, maintaining material quality.

-

High Precision Cutting:

The cutting machine offers exceptional accuracy, enabling precise cutting of stainless steel sheets or strips with tight tolerances. This precision is essential for industries requiring exact dimensions, such as automotive, aerospace, and architecture, where even slight deviations can affect product performance and assembly. The machine’s high-quality cutting tools ensure clean, sharp edges without the need for extensive post-processing. -

Versatile Cutting Capabilities:

Designed to accommodate various cutting methods, such as shearing, laser cutting, or plasma cutting, the machine can handle different thicknesses and grades of stainless steel. This versatility allows manufacturers to cut thin gauge sheets or thicker plates with ease, making the machine suitable for a wide range of applications. The ability to switch between cutting styles also helps optimize production based on material type, thickness, and the complexity of the cut. -

Durable Blade and Tool Materials:

The cutting machine is equipped with high-strength blades and cutting tools made from materials like carbide or diamond-coated steel, capable of handling the toughness and wear resistance of stainless steel. These durable components ensure long-lasting performance and minimal tool wear, reducing the need for frequent blade replacements and lowering overall maintenance costs. The machine is built to endure the repeated impact and stress of cutting stainless steel without losing efficiency or precision. -

Automated Feed and Alignment Systems:

Advanced automation in the machine helps regulate material feed and ensures perfect alignment during cutting. This reduces manual intervention, enhances speed, and guarantees that the stainless steel sheets or strips are positioned correctly for each cut. The automated system can be programmed to handle continuous cutting tasks, optimizing production workflow and reducing errors, particularly in high-volume operations. It also allows for easy setup adjustments when switching between different cutting parameters or sheet sizes. -

Surface Protection During Cutting:

The machine incorporates mechanisms to safeguard the surface finish of stainless steel during the cutting process. Features like protective clamps, smooth feeding tables, and non-abrasive surfaces prevent scratches, dents, or deformation of the material. This is especially important for applications where the visual appearance and corrosion resistance of stainless steel must be maintained, such as in decorative panels, kitchen appliances, or medical equipment. By protecting the surface, the machine ensures that the final product retains its aesthetic and functional qualities.

Where Our Machine is Used